Monorail and Metro

Monorail and Metro

Our contribution to the monorail and metro infrastructure includes the fabrication and installation of high-precision steel structures designed to enhance passenger movement, platform safety, and operational efficiency. The LMA extension structure at Wadala Monorail Depot was engineered to support platform expansion works and optimize boarding alignment.

Project Details

Project Name: Medha SMH Rail Pvt Ltd (MMRDA)

Project Title: Fabrication & Supply of LMA Extension Structure Erection– Platform Extension – Wadala Monorail Depot

Durations: 5 Months

Year of Completion: 2025

Project Description

The project consisted of designing, fabricating, and supplying the LMA (Load Measurement & Alignment) extension structure required for platform expansion at Wadala Monorail Depot under MMRDA. The fabricated steel structure enabled improved passenger access and operational alignment for monorail train docking.

This Included:

-

Structural steel fabrication for platform extension framework

-

Precision assembly for accurate alignment with monorail rolling stock

-

Load-bearing structure designed for high-traffic passenger flow

-

Surface finishing for anti-corrosion and durability

Technical Features

Heavy-Duty Structural Steel

Engineered to withstand high load, vibration, and continuous passenger traffic.

Corrosion-Resistant Surface Coating

Protective treatment ensures long-term durability and rust prevention.

Precision Alignment & Positioning

Ensures perfect interface between monorail coach and platform.

High Structural Stability

Designed to support dynamic loads and ensure safe passenger movement.

Industrial-Grade Welding & Fastening

Strong joints deliver reliable performance and structural integrity.

Customized Fabrication

Built exactly as per engineering drawings and technical requirements.

Scope of Work

-

Fabrication of steel structures for platform extension

-

Material handling, transportation and unloading

-

Trial assembly and dimensional quality checks

-

Surface finishing and corrosion-resistant coating application

-

Supply and delivery to Wadala Monorail Depot

Erection & Installation Scope

-

Positioning and alignment of platform structural members

-

Bolting, welding & on-site fit-adjustments

-

Precision verification with measurement instruments

-

Safety barricading and controlled execution within live transit zone

-

Final inspection and certification with client engineering team

Execution Highlights

-

Fast-track project completed within the scheduled 5-month duration

-

Execution conducted within an active metro/monorail operational area with full safety compliance

-

Zero disruption to depot and passenger operations

-

Seamless coordination with MMRDA engineers for technical approval

-

Delivered high-quality fabrication meeting design specifications

Key Achievements

-

Successfully extended platform to improve boarding & crowd management

-

Increased passenger movement efficiency & safety

-

Structural components integrated smoothly with existing framework

-

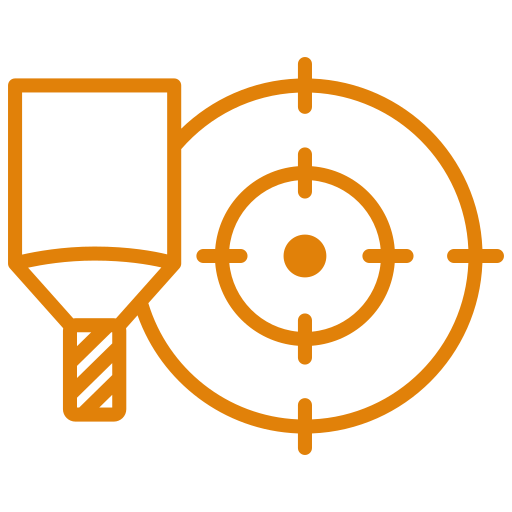

Achieved client appreciation for precision execution & quality control

-

Project completed within timeline and budget constraints

Appreciation Letter